The lagoon MBBR, or moving bed biofilm reactor, is a proven technology for the removal of lagoon ammonia through biological nitrification. In this article, we’ll describe MBBR technology and how it’s been adapted for lagoon ammonia treatment. Then, we’ll explain how Triplepoint’s patented NitrOx® Process improves on the lagoon MBBR by adding a heating element to ensure year round nitrification in cold climates and show how an installation performed during the brutal Polar Vortex cold snap in January 2019.

What Is an MBBR?

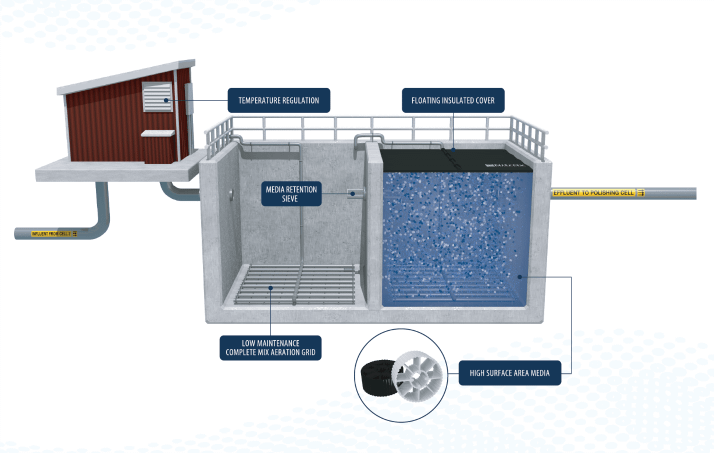

MBBR stands for Moving Bed Biofilm Reactor: A tank or reactor houses loose plastic carrier pieces (also known as media) that provide a surface to which waste-consuming microorganisms can attach and grow, creating biofilm. This concentrated biomass provides high volume wastewater treatment in a small footprint.

An aeration grid at the bottom of the reactor keeps the media moving, suspended in the wastewater. The movement of the media in the wastewater keeps the bacteria in contact with the waste and keeps the growth in check by “cleaning” the media pieces as they bump into each other and the walls of the reactor.

Invented in Norway in the late 1980s, the MBBR has become a common wastewater treatment process, popular due to its compact size, ease of operation, and ability to adjust to varied flows and loadings.

Because an MBBR maximizes biological treatment by optimizing conditions for bacterial growth, it can be configured for a variety of applications: to provide single-or two stage BOD removal, nitrification, BOD and nitrification, or denitrification.

As a primary wastewater treatment process, an MBBR typically consists of two reactors or tanks, the first to treat BOD and the second to polish BOD and treat ammonia-nitrogen, followed by a clarifier to screen out solids.

A lagoon MBBR is a tertiary treatment process added to a lagoon system for the purpose of ammonia or nitrogen removal through biological nitrification or denitrification.

The Lagoon MBBR

A lagoon system can provide sufficient BOD treatment, so a lagoon MBBR is used solely for ammonia or nitrogen removal, preserving the existing infrastructure and ease of operation of the lagoon.

Removing lagoon ammonia through nitrification requires a specific set of conditions:

- Reduced BOD: BOD-removing heterotrophic bacteria outcompete nitrifying bacteria, so BOD levels must be reduced sufficiently to give nitrifiers a chance to work. Generally, a BOD level of 20–30 mg/L is required, a level most lagoons are able to achieve.

- Lagoon pH of 7.5–8.0: Lagoon nitrification is pH sensitive; ammonia treatment rates decline significantly at pH values below 6.8. Most municipal wastewater lagoons will naturally have a pH in this range.

- Adequate DO levels: Wastewater lagoon nitrification consumes large quantities of oxygen: 4.6 lbs of O2 per every pound of ammonia oxidized. In order for lagoon nitrification to occur, a working dissolved oxygen level of 3.0 mg/L is required and a DO level of 5.0 mg/L is optimal.

- Adequate mixing: Mixing is critical in order to bring the oxygen, nitrifiers and ammonia into contact with each other for efficient treatment. Moreover, without mixing, sludge can build up or short circuiting can occur.

- Biomass: Nitrifying bacteria are attached growth organisms, so they need surfaces to grow on. The more surface area is available, the more nitrifiers the system can cultivate. MBBR carrier media is designed to maximize the surface area on each plastic piece.

- Temperature: Nitrification slows as temperatures drop. The optimal range for lagoon nitrification is 82 to 97° Fahrenheit, which is clearly unrealistic for a wastewater lagoon. Acceptable rates of lagoon nitrification can be achieved at or above 68° F. Many lagoons can achieve reasonable ammonia removal during the summer but struggle in the winter, when nitrification slows or stops completely.

For more on lagoon ammonia and the key factors for nitrification, watch our You Tube video.

The lagoon MBBR optimizes most conditions for biological nitrification: It supports biomass with carrier media for nitrifying bacteria to grow on and it provides dissolved oxygen and mixing via an aeration grid. The biggest challenge is with temperature: Because the MBBR follows the lagoon, influent water temperatures can be too cold to support nitrification in winter.

Accounting for the Limitations of Lagoon MBBR Ammonia Treatment

How can a lagoon MBBR remove ammonia when the water is too cold for nitrification? One option is to increase the biomass. Increasing the amount of carrier media can increase nitrifying bacteria density by giving them more surfaces to attach to. The challenge is the amount of media required to compensate for the cold temperature and the size of the reactor needed to contain them. Adding hundreds of cubic feet of media can cost hundreds of thousands of dollars and require a basin the size of three or four football fields.

Triplepoint’s NitrOx Lagoon MBBR

Triplepoint’s patented NitrOx Process solves the temperature limitations of the lagoon MBBR by heating the reactor influent—only when needed and just enough to ensure biological nitrification. Because the temperature increase is minor, to a target between 36.5 and 41° F, and only required a few months per year, energy costs are kept to a minimum. Temperature is regulated automatically, too, preserving the ease of operation of the lagoon system.

NitrOx vs. the Polar Vortex

Following a successful pilot, the City of De Soto, Iowa, installed a full NitrOx system to upgrade their existing three-cell aerated lagoon with ammonia removal. Lack of available land was a challenge: the solution would have to have a small footprint and fit onto the existing site. The lagoon system’s current flow is just above 100,000 gpd, but the NitrOx was sized to treat up to 630,000 gpd to account for the community’s future growth.

Although De Soto’s lagoon system was achieving adequate nitrification during the summer, cold temperatures would put the city out of compliance during the cold winter months, unable to meet an ammonia effluent limit of below 5 mg/L. Since the NitrOx was installed, De Soto had been reliably meeting its ammonia limit. But how would it perform in a brutal cold snap?

Great, as it turns out. Despite three straight days of temperatures well below 0° Fahrenheit during the “Polar Vortex” of late January 2019 and influent ammonia of 16.9 mg/L, De Soto’s NitrOx system put out effluent ammonia below 0.10 mg/L, well under permit.