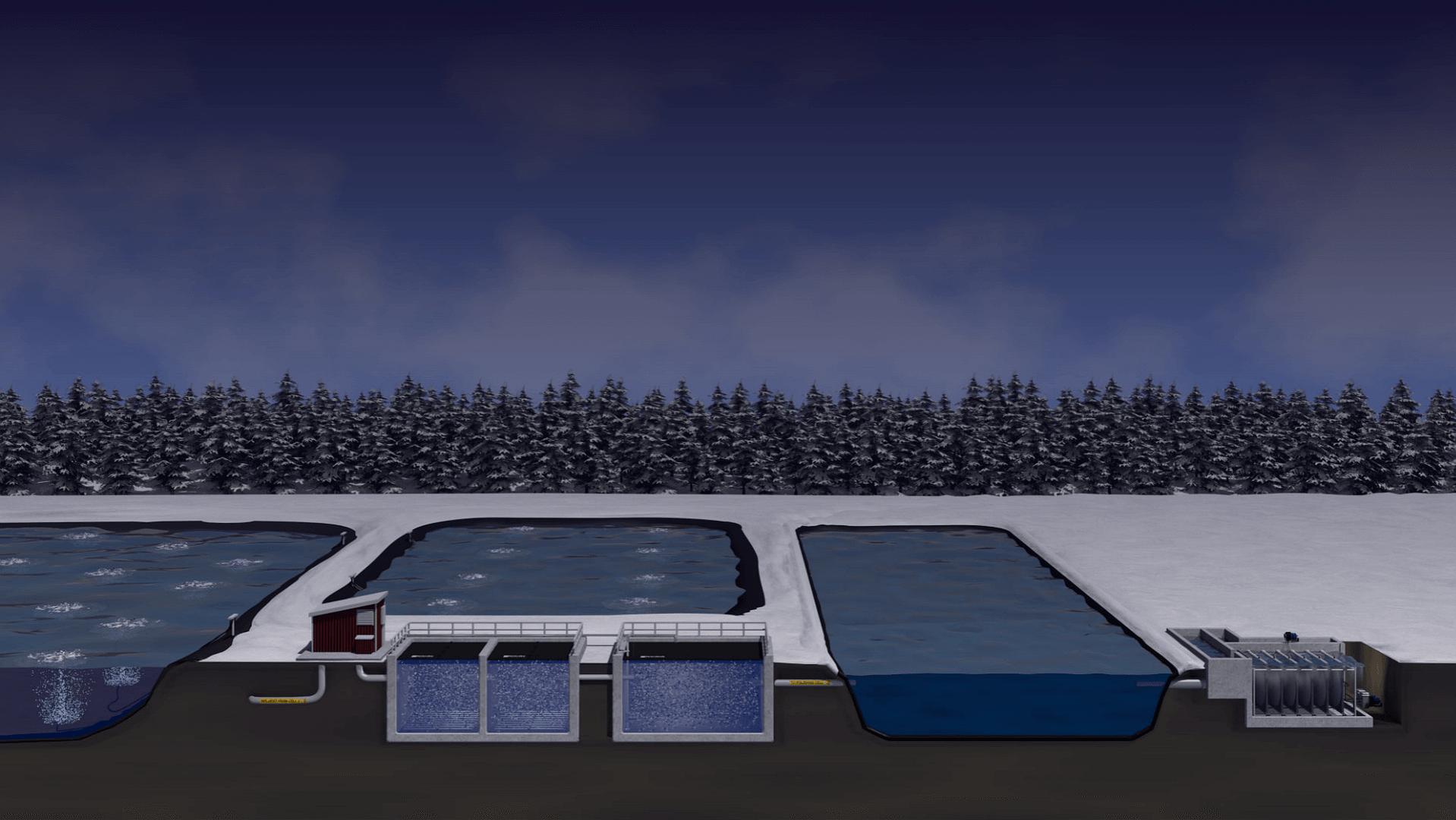

Lagoons should be reinvented, not replaced.

For hundreds of years, lagoons have provided reliable, cost-effective, and low maintenance wastewater treatment for municipalities and industries. Nowadays, lagoon owners are increasingly challenged to meet stricter effluent requirements, expand capacity, or simply upgrade antiquated or underperforming equipment.

That’s where we come in. Triplepoint’s innovative lagoon technologies leverage existing infrastructure to ease the financial burden of upgrades while reinventing lagoons to meet new effluent limits.

Wastewater Lagoon Technologies

Reliable. Cost effective.

Easy to operate.

Wastewater Lagoon Technologies

Our Ares Lagoon Aerator is more than an evolution of our industry-leading MARS™ Aerator…it represents a fundamental redesign and reengineering of the technology. Like MARS, Ares combines mixing and aeration in one portable unit, but has been vastly improved.

Our patented NitrOx+D Process is designed to cost-effectively upgrade your lagoon system to meet a total nitrogen or nitrate requirement.

Triplepoint’s PhosBox is a low maintenance, tertiary lagoon filtration system designed to achieve effluent phosphorus limits as low as 0.5 mg/L.

Wastewater Lagoon Solutions

Triplepoint’s technologies solve many common wastewater lagoon compliance and nuisance problems.

Partner with Triplepoint on your next lagoon project and let us put our specialized expertise to work for you.

We’re ready to help.

Whether you’re looking for an ammonia solution for your lagoon or just have a quick question about algae, we’re here for you.

We want to be your #1 resource for all things wastewater lagoons. If we can help you, please don’t hesitate to get in touch.

"*" indicates required fields