An aerated lagoon can be one of the most efficient, cost-effective, and low-maintenance methods of wastewater treatment. Because aeration can account for 50–60% of energy costs, it’s important to consider design conditions when determining the type and amount of aeration required. This article will provide an overview of the factors, namely SOTE, SAE, aeration type, flow rate, and lagoon depth, that must be taken into account when designing an aerated lagoon system.

The designer or engineer must understand the relationship between these sometimes competing factors, how to calculate them, and their effect on the efficiency of an aerated lagoon system.

1. SOTE

SOTE stands for Standard Oxygen Transfer Efficiency, the measurement of how much oxygen is transferred by a given aerator in clean water under the American Society of Civil Engineers’ testing standards. It is commonly used in aeration calculations to determine how much air is required to provide the necessary pounds/kilograms of oxygen needed for aerated lagoon treatment. The higher the percentage SOTE number, the less air is needed.

Bubble size is the single biggest factor in determining SOTE. The smaller the bubble, the higher the efficiency. This is due to the ratio of the bubble’s surface area to its volume, as well as the speed at which it rises through the water (the larger the bubble, the faster it rises).

SOTE has a role to play in aerated lagoon efficiency because if less air is needed to provide the necessary oxygen, then potentially a lower blower horsepower is required. This can lead to lower energy costs. However, it is important to realize that SOTE alone is not a measure of energy efficiency: backpressure together with the air requirement determines horsepower needed. For example, one fine bubble diffuser could have an SOTE of 3% per foot of depth, but have a higher operational backpressure than an alternative diffuser that is capable of 2% per foot. In that case, while the first diffuser will require less air to provide the necessary pounds of oxygen, it could require the same amount of horsepower/energy consumption as the second due to the blower having to work harder to overcome the additional backpressure.

2. SAE

SAE, or Standard Aeration Efficiency, is intended to help the designer compare the operating costs of different aerators in a particular aerated lagoon application. Measured in terms of pounds of oxygen per horsepower hour, it incorporates both SOTE and blower horsepower. As a result, it is a more complete metric that allows different aerators’ energy efficiencies to be compared side by side. While SAE is rarely factored into the actual aeration calculations, it’s a good metric for directly comparing the energy efficiency of different technologies.

Difficulties with SOTE and SAE

There are a number of difficulties in making apples-to-apples comparisons of different aerators based solely on SOTE or SAE. For starters, there are different standards and methods for testing, both within the United States (ASCE), and abroad. Secondly, many aerator manufacturers advertise high SOTEs with very little data to back them up. (We’ve seen independent test results that came in at one-third to one-half of the manufacturer’s claims). An aeration system designer should never select equipment without certified independent lab results to confirm the manufacturer’s numbers. Preferably, the tests should be conducted by the same lab under the same conditions.

Moreover, the purpose of aeration in a wastewater lagoon system is more than just to add the necessary oxygen to water: it is also to mix. Mixing ensures that the organic matter, bacteria, and oxygen all come into contact with each other, thereby facilitating the wastewater treatment process. Without proper mixing, your lagoon could have the most energy-efficient aeration possible, but still not achieve your effluent objectives. For more information on mixing see our article, Wastewater Mixing Alleviates Odor & Sludge Issues.

3. Fine vs. Coarse Bubble vs. Surface Aeration

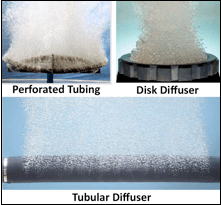

Fine bubble aeration: Fine bubble diffusers generally produce bubbles of about an eighth of an inch in diameter or less that are fairly consistent in size. These smaller bubbles have more contact area per volume of air, and they tend to climb the water column more slowly. This results in more oxygen transferred, more efficient lagoon aeration overall, and thus a higher SOTE and SAE. For fine bubble diffusers, the SAE can range from 4–7.0 lbs or more of oxygen per horsepower hour. For more information see our article, Fine Bubble Aeration in Wastewater Lagoons—Pros & Cons.

Coarse bubble aeration: Coarse bubble diffusers produce bubbles larger than a quarter of an inch in diameter. They are usually irregular and inconsistent, sometimes producing very large bubbles of an inch or two, interspersed with smaller ones. Generally, coarse bubbles are regarded as effective mixers; however, they are less efficient than fine bubbles at providing the necessary oxygen. For coarse bubble diffusers, the SAE tends to be about 2–3 lbs. of oxygen per horsepower hour. See our article on Lagoon Coarse Bubble Aeration: Pros & Cons.

4. Flow Rate

The amount of air pushed through a diffuser has an effect on the efficiency at which it operates in an aerated lagoon. For example, if airflow per unit is increased, aeration efficiency decreases because backpressure generally goes up and the blower needs to consume more energy to provide the required air. Contrarily, running an aerator at the low end of the design range can create very efficient SOTE; however, this will likely result in the need for more aerators. More aerators will increase capital cost for purchasing the diffusers in addition to extra piping infrastructure for delivering air. In addition, more aeration equipment leads to a higher installation labor cost and increases the long run maintenance costs.

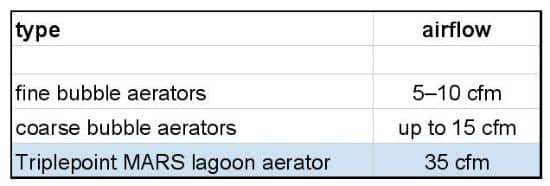

Generally there is an optimal airflow rate for each diffuser technology. The chart below shows the flow rates you can expect to find with different aerated lagoon technologies.

The Ares Aerator has a higher airflow capacity per unit due to its combination of both fine and coarse bubble diffusion in one portable unit.

5. Depth

For diffused aeration systems, the deeper the aerator, the more efficient it is. While not perfectly linear, many aerators provide their SOTE as a measure of depth. For example, a good coarse bubble diffuser may produce 1% of SOTE per foot of depth, while a good fine bubble diffuser may produce about 2% of SOTE per foot of depth.

There is a tradeoff between depth, energy efficiency, and capital costs. For example, if a lagoon is 15 feet vs. 10 feet deep, less air and aeration equipment is required to provide the needed oxygen; however, the backpressure will be higher, requiring a larger blower that will consume more energy. Contrarily, if the depth is 5 feet, the backpressure is lower, but there is more air and aeration equipment required to diffuse that air, driving up capital costs. Generally, optimal aeration design for a fine bubble system is between 8 and 10 feet of depth.

For surface aerators, this relationship is not as clear. A surface aerator in a deep lagoon of 15 feet or more will struggle to provide enough mixing than it would in a shallow lagoon of 5 feet or less. However, it will not use any more power either. Generally it is understood that surface aerators, depending on their style and horsepower, are only capable of mixing the first 5–6 feet of the water column.

In conclusion

When designing an efficient aerated lagoon, it is important to be aware of the pitfalls and tradeoffs involved during design. SOTE does not equal energy efficiency, and, while SAE is a way to compare the relative energy efficiencies of each aeration unit, it ultimately fails to account for the importance of mixing. In addition, the interplay between depth, airflow per diffuser unit, and blower backpressure all play a role in determining blower horsepower and energy consumption. By understanding the determining factors and tradeoffs involved, you will better be able to balance them in order to design an optimized aerated lagoon.

Contact Triplepoint for Assistance Designing an Efficient Aerated Lagoon System—we can provide you with design calculations, budgetary costs, preliminary layouts, and a lifecycle cost analysis.